Wall And Roof Systems For Timber Frame Buildings

Structural Insulated Panels (SIP's)

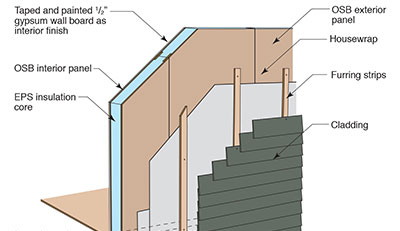

A Structural Insulated Panel (SIP) is an energy-efficient building material that consists of an insulating foam core sandwiched between two structural facings, commonly oriented strand board (OSB). It is the best methode to enclose a timbeer frame building, as they offer high thermal performance, quick assembly, and superior strength.

Using SIPS in Timber Frame Buildings:

In a timber frame building, SIPS can be used for walls, floors, and roofs. The combination of the timber frame structure and SIPs helps create a durable, well-insulated, and energy-efficient building.

Benefits of SIPs in Timber Frame Construction:

Energy Efficiency:

The continuous insulation of the SIP reduces thermal bridging and air infiltration, resulting in lower energy consumption and heating/cooling costs.

Strength and Durability:

The SIPs add structural integrity to the timber frame. When properly designed and installed, the panels can withstand high wind loads and other environmental stresses.

Quick Installation:

SIPs can be prefabricated off-site and delivered to the construction site, allowing for faster assembly compared to traditional methods of framing and insulation.

Design Flexibility:

SIPs are available in various thicknesses and sizes, providing design flexibility. This is especially useful in creating energy-efficient homes with custom layouts.

Reduced Material Waste:

Since SIPs are factory-produced, there's less material waste on-site compared to conventional framing methods.

Sound Insulation:

SIPs offer better sound insulation compared to traditional framing, which can make for a quieter interior environment.

Common Applications:

Wall Panels:

SIPs are typically used for exterior and interior walls, providing both structure and insulation in one component.

Roof Panels:

SIPs are also used in roofing systems to create a strong, well-insulated roof.

Floor Panels:

SIPs can be used as subfloor panels to create a solid, insulated floor system.

Installation in Timber Frame Buildings:

The timber frame provides the skeleton of the building, supporting the weight of the SIPs. The timber frame include vertical posts, horizontal beams, and rafters that are spaced at intervals to align with the SIP panels.

Sealing:

To ensure a tight seal and maximize insulation, all panel joints should be sealed with appropriate sealant or tape to prevent air leaks.

Finishing:

Once the SIPs are in place, the exterior and interior surfaces can be finished with siding, drywall, or other materials.